Lean Manufacturing Management: Optimize Your Production Processes

In an increasingly competitive global economy, manufacturing companies must constantly seek ways to improve their operational efficiency. Lean Manufacturing Management has become an essential approach to optimize production processes, reduce costs, and increase customer value. This article presents the fundamental principles of Lean, its concrete benefits, and a step-by-step methodology to implement it in your organization.

Summary

- What is lean manufacturing management?

- The fundamental principles of lean manufacturing

- Differences between lean manufacturing and traditional methods

- The benefits of lean manufacturing for businesses

- How to implement lean manufacturing in your organization

- Conclusion

What is lean manufacturing management?

Definition and origin of lean manufacturing

Lean Manufacturing is a systematic approach aimed at eliminating waste while creating value for the end customer. This methodology has its roots in the Toyota Production System (TPS), developed in Japan after World War II by Taiichi Ohno and Eiji Toyoda. Faced with limited resources, Toyota developed a philosophy centered on eliminating non-value-added activities and process optimization.

The term “Lean” was popularized in the 1990s by the book “The Machine That Changed the World” by James Womack and Daniel Jones, which documented how this approach enabled Toyota to produce higher quality vehicles with fewer resources than its Western competitors.

The fundamental principles of lean manufacturing

Lean Manufacturing is based on five key principles:

- Define value from the customer’s perspective: understand what the customer is willing to pay for and what constitutes real added value.

- Identify the value stream: map out all the steps required to turn raw materials into finished products, identifying value-added and non-value-added activities.

- Create continuous production flow: organize processes so that products move without interruption or delay.

- Establish a pull system: produce only what is requested by the customer, when it is requested.

- Pursue perfection: engage in continuous improvement (Kaizen) to constantly optimize processes.

Differences between lean manufacturing and traditional methods

| Aspect | Traditional Management | Lean Manufacturing |

|---|---|---|

| Production | Large batches | Continuous flow, small batches |

| Inventory | High (safety stock) | Minimal (Just-in-Time) |

| Quality | End-of-process control | Built-in at each step (Poka-Yoke) |

| Improvement | Occasional projects | Daily continuous improvement |

| Organization | Hierarchical | Autonomous teams |

| Waste | Tolerated | Systematically eliminated |

Unlike traditional approaches that focus on maximizing equipment use and producing in large batches, Lean Manufacturing emphasizes operational flow and waste elimination to better meet real customer needs.

The benefits of lean manufacturing for businesses

Waste and cost reduction

Lean Manufacturing identifies eight types of waste (or “muda” in Japanese) that must be eliminated:

- Overproduction: producing more than needed or before it is needed

- Waiting time: idle periods for people, machines, or products

- Unnecessary transport: avoidable movement of materials or products

- Overprocessing: steps that do not add value for the customer

- Excess inventory: surplus raw materials, work-in-progress, or finished goods

- Unnecessary motion: avoidable operator movements

- Defects and rework: errors requiring correction

- Underutilized talent: wasting employee ideas and skills

By methodically addressing these wastes, companies significantly reduce their operating costs. For instance, implementing Just-in-Time (JIT) reduces storage costs, while improving quality reduces costs related to defects and rework.

Improved quality and productivity

Lean Manufacturing integrates quality directly into the production process rather than controlling it afterward. This approach uses tools like Poka-Yoke (error-proofing) and Andon (visual alert systems) to detect and fix problems at the source.

Productivity also improves through the elimination of delays and bottlenecks, as well as the standardization of best practices. In addition, preventive equipment maintenance (TPM - Total Productive Maintenance) and performance monitoring via OEE (Overall Equipment Effectiveness) further boost productivity.

Companies that have adopted Lean often report productivity gains of 15 to 30% in the first few months of implementation.

Increased customer satisfaction

By focusing on customer-perceived value, Lean Manufacturing significantly enhances customer satisfaction through improved product quality, shorter and more reliable delivery times, and greater flexibility to meet specific demands and continuously improve products.

The pull system synchronizes production with actual demand, reducing stockouts and avoiding the overproduction of low-demand items.

Strengthened employee engagement

The Lean approach considers employees as the company’s most valuable resource. It actively involves them in process improvement through training and skills development. It also empowers work teams, particularly through participation in Kaizen (continuous improvement) activities, embracing collaborative problem-solving.

This increased involvement leads to greater motivation, lower absenteeism, and improved talent retention. Employees also develop a sense of ownership by directly contributing to the company’s improvement.

How to implement lean manufacturing in your organization

There are many lean methodologies

There are many lean methodologies

Identify and eliminate waste

The first step is to analyze current operations to identify different forms of waste:

- Train teams to recognize the 8 types of waste

- Organize “waste hunts” on the shop floor

- Implement the 5S methodology to organize the workspace:

- Seiri (Sort)

- Seiton (Set in order)

- Seiso (Shine)

- Seiketsu (Standardize)

- Shitsuke (Sustain)

- Document and quantify identified wastes

- Prioritize actions based on their potential impact

The 5S method is often the ideal entry point into a Lean initiative, as it delivers visible results quickly and lays the groundwork for more complex improvements.

Map the value stream

Value Stream Mapping is a powerful tool to visualize the entire production process from suppliers to customers:

- Select a product family to analyze

- Draw the current state, including:

- Physical flow of materials

- Information flow

- Cycle times, changeover times, inventory levels

- Performance indicators such as takt time (customer demand rate)

- Analyze opportunities for improvement

- Draw the desired future state

- Develop an action plan to move from the current to the future state

This mapping helps identify non-value-added steps and visualize how to optimize the flow to reduce lead times and improve responsiveness.

Create continuous production flow

To create continuous flow, several techniques can be implemented:

- Reorganize workshops into production cells grouped by product family

- Balance workstations to avoid bottlenecks

- Reduce changeover times using the SMED method (Single-Minute Exchange of Die)

- Standardize processes to ensure repeatability and reliability

- Implement visual management to facilitate flow supervision

Reducing changeover times is particularly critical to enable small-batch production without efficiency loss. The SMED method often reduces changeover time by over 50%.

Implement a pull system

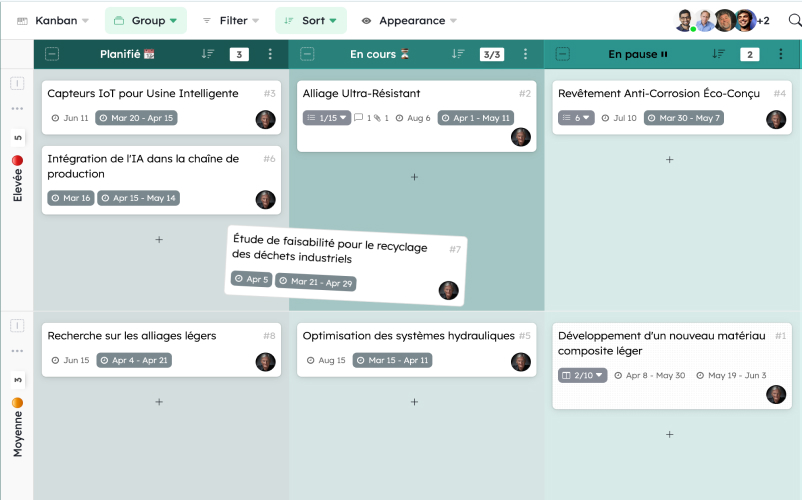

Click the Kanban to download your custom model

Click the Kanban to download your custom model

The pull system is one of the core concepts of Lean Manufacturing:

- Define production trigger rules based on actual consumption

- Implement a Kanban system (cards, containers, or electronic signals)

- Calculate the optimal number of Kanbans for each item

- Train operators to follow the pull system discipline

- Establish parts supermarkets at process interfaces

The Kanban system acts as a regulator that limits work-in-progress and synchronizes production with actual consumption, avoiding overproduction while ensuring product availability.

Pursue perfection with continuous improvement

Continuous improvement (Kaizen) is the key to sustaining the Lean approach:

- Set clear, visible performance indicators (dashboards)

- Hold short daily meetings to track performance and solve problems

- Establish continuous improvement rituals (Kaizen workshops, PDCA - Plan-Do-Check-Act)

- Train teams in problem-solving tools (5 Whys, Ishikawa diagram, etc.)

- Gradually integrate more advanced methods like Lean Six Sigma

For companies more mature in their Lean journey, integrating Lean Six Sigma adds a statistical dimension to process improvement, particularly for reducing variability and further improving quality.

Conclusion

Lean Manufacturing Management is much more than a simple method for optimizing production; it’s a genuine business philosophy that puts value creation and waste elimination at the heart of all decisions. By gradually adopting its principles and tools, companies can not only significantly improve their operational performance but also create a more engaging work environment and a culture of continuous improvement.

Implementing Lean is not a one-off project but a continuous journey requiring long-term commitment from leadership and all employees. The most successful organizations are those that adapt Lean principles to their specific context rather than blindly applying tools.

In this era of digital transformation, Lean Manufacturing continues to evolve to integrate the new technologies of Industry 4.0, thus creating a “Digital Lean” that combines the elimination of physical waste with the optimization of digital information flows.

The question is no longer whether your company should adopt Lean Manufacturing, but rather how to implement it effectively to remain competitive in an ever-changing global market.

To go further

If you're interested in this topic, here are 3 options:

-

1

Try Kantree here, it is free and you don’t need any credit card

-

2

If you want to learn more about how Kantree can adapt to your challenges, make an appointment with an expert on your use case.

-

3

Are you willing to join +1500 professionals receiving our advices and news on digitalization, collaboration, productivity? Register to our newsletter here.

If you found this article useful, consider sharing it. You can do so easily below.