How to manage an industrial project: Step-by-step guide

TL;DR

Industrial project management requires a methodical approach in 6 essential steps: definition of SMART objectives, rigorous planning of resources and deadlines, building a team with well-defined roles, constant monitoring with relevant indicators, quality control integrated throughout the process, and final evaluation of results. This guide offers comprehensive support for each step, enriched with concrete examples and tools adapted to the industrial context. Follow these recommendations to significantly increase the chances of success of your industrial projects and obtain tangible results in a complex and demanding environment.

Table of contents

- 1. Define the objectives of the industrial project

- 2. Planning and preparation of the industrial project

- 3. Build a project team and define roles

- 4. Monitoring and management of project progress

- 5. Quality control and resource management

- 6. Conclusion and evaluation of results

- Comparative table of tools

Industrial project management requires a methodical and structured approach to ensure the success of initiatives in a complex and demanding environment. With 86% of companies having launched projects related to industry 4.0, mastering these skills becomes crucial to remain competitive. This guide accompanies you through the essential steps to successfully carry out your industrial projects, from defining objectives to evaluating results.

The industrial sector presents unique challenges: production constraints, complex resource management, compliance with safety standards and cost optimization. Rigorous industrial project planning forms the basis of success and helps avoid common pitfalls that can compromise results.

1. Define the objectives of the industrial project

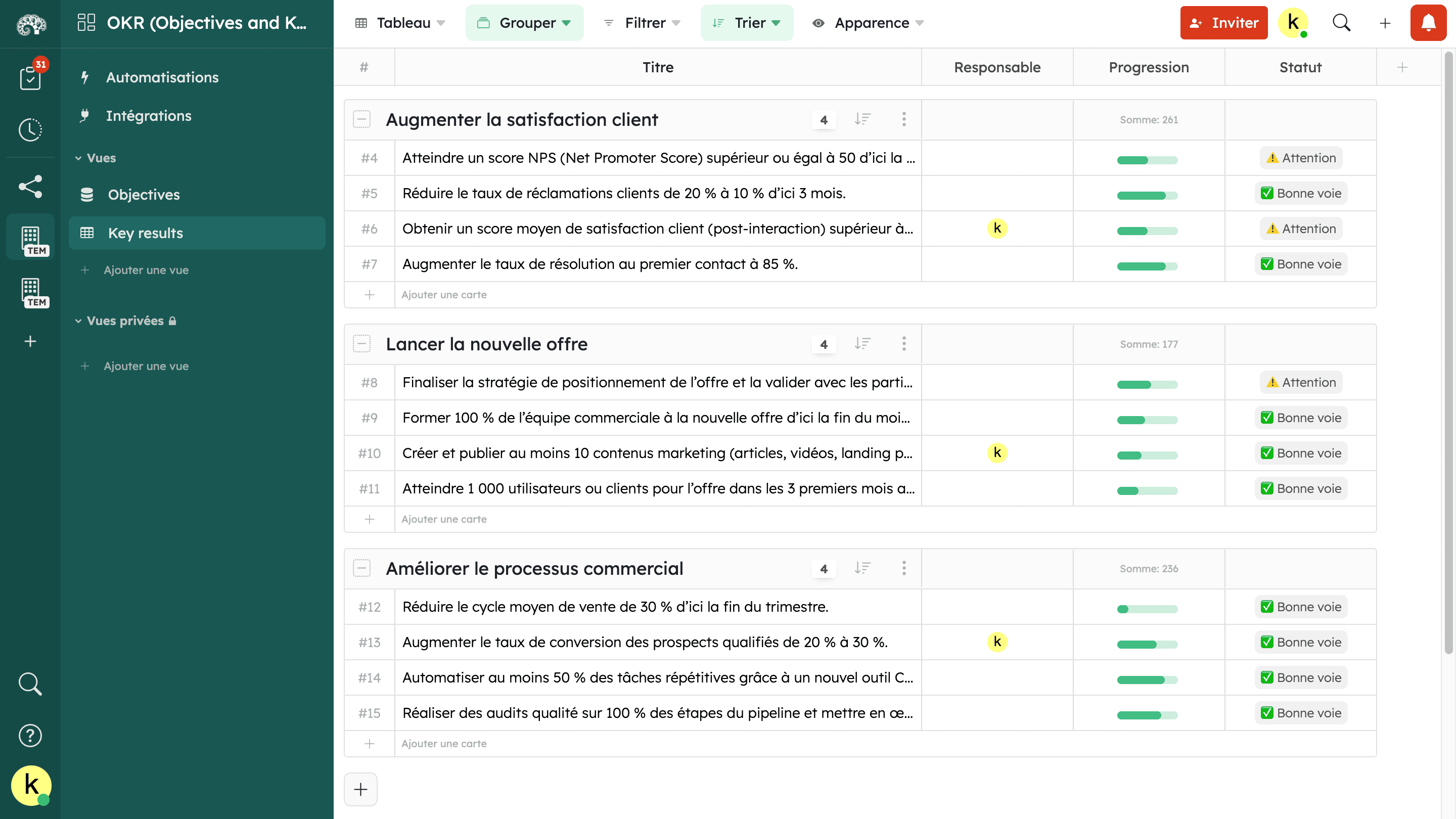

☝️ Click on the image above to get your OKR (objectives key results) template directly.

Why a clear definition of objectives is crucial

The precise definition of objectives constitutes the foundation of any successful industrial project. Without clear objectives, teams lose their direction and resources are wasted. In the industrial environment, where financial and operational stakes are considerable, this step often determines the difference between success and failure.

Well-defined objectives allow all stakeholders to align on a common vision. They serve as a reference for making decisions throughout the project and facilitate communication between different departments. In addition, they constitute the basis for measuring performance and evaluating return on investment.

Examples of SMART objectives in an industrial project

The SMART method (Specific, Measurable, Achievable, Realistic, Time-bound) proves particularly effective in the industrial context. Here are concrete examples:

Production objective: “Increase the production capacity of the assembly line by 25% within 6 months, going from 1000 to 1250 units per day, with a budget of €500,000.”

Quality objective: “Reduce the defect rate from 3% to 1% over the next 12 months through the implementation of a new automated quality control system.”

These objectives integrate all SMART criteria and provide a precise framework for project management.

2. Planning and preparation of the industrial project

Identify the necessary resources: human, material and financial

Resource planning represents a major challenge in industrial project management. This step includes six essential dimensions: content definition, project breakdown (WBS), resource determination, duration estimation, cost evaluation and risk identification.

Human resources include not only the necessary workforce, but also their specific skills. An automation project will require robotics engineers, maintenance technicians and operators trained in new technologies. Material resources encompass equipment, raw materials and necessary infrastructure.

The financial dimension must take into account direct and indirect costs, including equipment investments, training costs and possible production stoppages.

Deadline planning: industrial project management tools

Compliance with production deadlines represents a major issue in industry. Modern industrial project management tools offer functionalities adapted to the specificities of the sector.

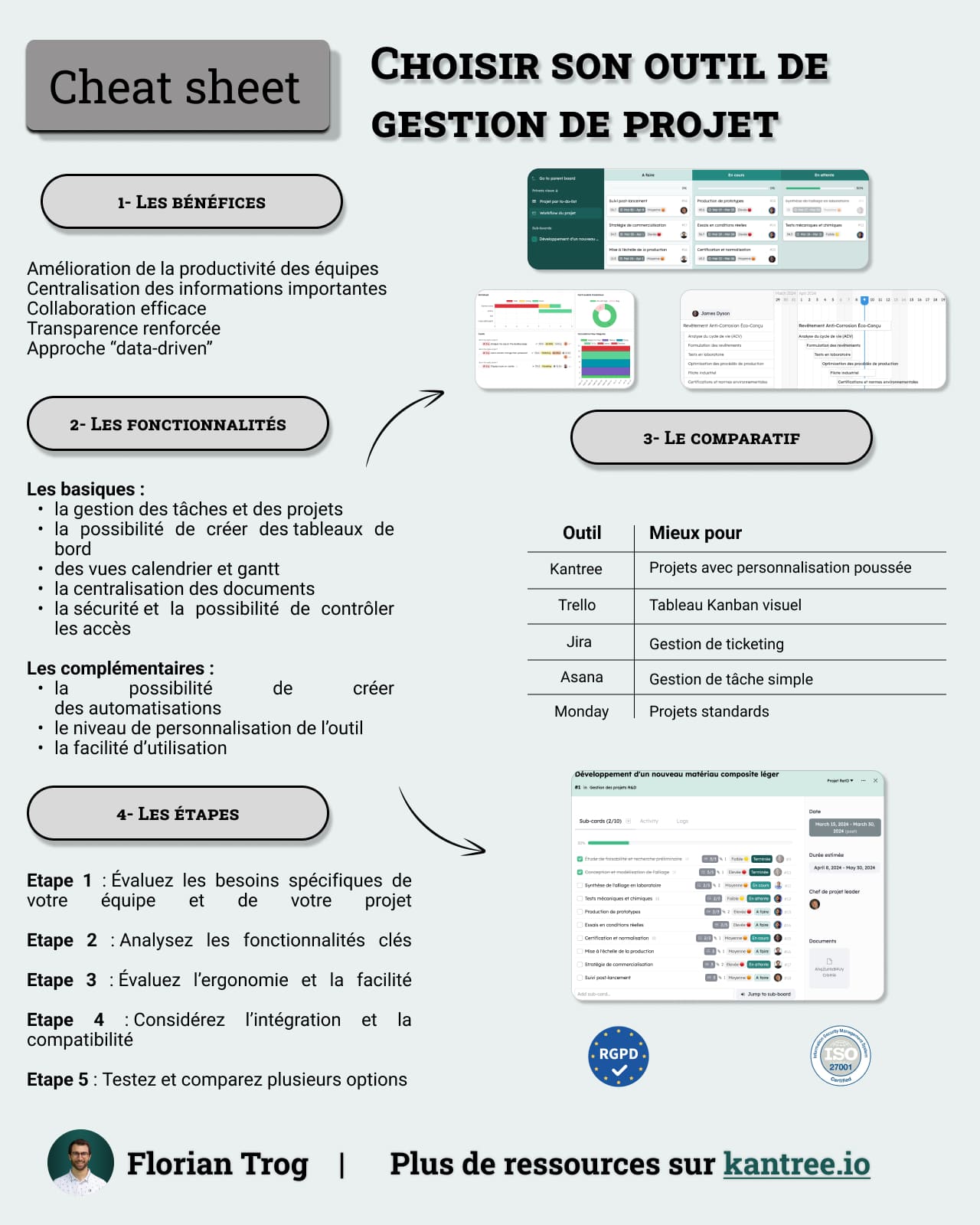

Among the most effective solutions, we find Monday.com (from €9/user/month) with its 200+ integrations, Asana ($10.99/user/month) recognized for its reliability, and Trello ($5/user/month) with its visual Kanban approach. The choice between Gantt or Kanban depends on the nature of the project and the company culture.

Risk assessment and implementation of preventive measures

The assessment of industrial risks constitutes a critical step that requires a systematic approach. Risks can be technical (equipment failures, quality defects), human (lack of skills, resistance to change) or external (delivery delays, regulatory changes).

The implementation of preventive measures includes the creation of contingency plans, team training and the establishment of emergency communication protocols. The use of the Deming wheel (Plan-Do-Check-Act) allows continuous improvement to be integrated into risk management.

3. Build a project team and define roles

How to choose the right members for your team

Building a high-performing team requires a balance between technical skills, industrial experience and relational abilities. Selection criteria include business expertise, ability to adapt to new technologies and aptitude for teamwork.

It is essential to diversify profiles to cover all aspects of the project: production engineers, quality specialists, maintenance experts, logistics managers. This diversity guarantees a holistic approach and reduces the risks of blind spots.

Key roles in an industrial project (project manager, production manager, etc)

Factory project management involves the coordination of multiple stakeholders with specific roles. The industrial project manager occupies a central position with extensive responsibilities: general coordination, planning, resource evaluation, specifications writing and supervision of the work of stakeholders.

The production manager ensures the interface between the project and current operations, guaranteeing business continuity. The quality engineer ensures compliance with standards and procedures, while the maintenance manager anticipates the maintenance needs of new equipment.

Importance of communication and coordination in the team

Effective communication constitutes the cement of the project team. The project methodologies in Kantree facilitate this coordination by offering collaborative tools adapted to industrial needs.

The implementation of communication rituals (weekly meetings, milestone reviews, reporting) helps maintain alignment and quickly identify deviations. The use of shared digital tools improves transparency and facilitates action tracking.

4. Monitoring and management of project progress

Use project monitoring tools to control progress

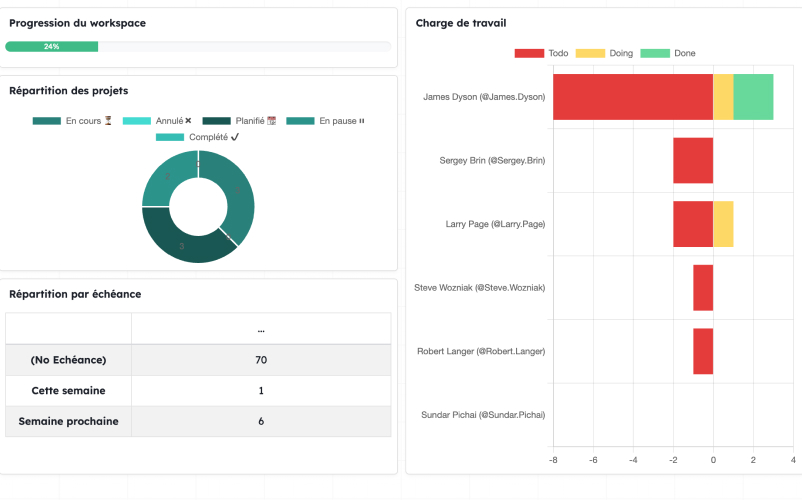

Industrial project monitoring requires tools adapted to the specificities of the manufacturing sector. Real-time dashboards allow progress to be visualized against defined milestones and potential deviations to be identified.

Key indicators include production throughput, cycle times, productivity indicators and cost measures. These metrics must be updated regularly to enable rapid and informed decision-making.

Manage the unexpected: how to adjust the project along the way

Managing the unexpected is an integral part of project management. Adjustments can concern deadlines, resources or even initial objectives. The key lies in the ability to react quickly while maintaining the overall consistency of the project.

The agile approach, adapted to the industrial context, allows greater flexibility in the face of change. Gemba walks offer an effective method to identify problems in the field and involve operators in resolution.

Dashboard and KPIs to monitor project performance

An effective dashboard must present essential information in a clear and concise manner. Industrial KPIs include performance metrics (OEE, yield rate), quality (defect rate, customer complaints) and costs (budget deviations, cost per unit produced).

Integration with a Cloud ERP allows automatic data consolidation and an overall view of project performance.

5. Quality control and resource management

Implement quality control processes throughout the project

Quality control should not be considered as a final step but as a continuous process integrated into each phase of the project. The planning and organization of quality control, the application of total quality principles and compliance with ISO 9001 standards constitute the pillars of this approach.

The implementation of regular control points allows deviations to be detected and corrected before they impact the final result. This preventive approach proves more economical than corrections after the fact.

Resource optimization and cost management

Industrial resource management requires a rigorous approach combining mastery of accounting and budgetary tools, development of decision support tools and effective communication with management. Activity monitoring via dashboards allows optimization opportunities to be identified.

Operational excellence in industry requires optimal use of available resources and a constant search for process improvement.

Continuous training and skills improvement of teams

The rapid technological evolution of the industrial sector requires constant investment in team training. Lean manufacturing management integrates this dimension of continuous skills improvement.

Training should not be limited to technical aspects but also include project management methodologies, digital tools and relational skills.

6. Conclusion and evaluation of project results

How to measure the success of your industrial project

The evaluation of the success of an industrial project is based on multiple criteria: compliance with deadlines, budget control, achievement of performance objectives and stakeholder satisfaction. Quantitative indicators must be complemented by a qualitative assessment of the impact on the organization.

Measuring return on investment (ROI) constitutes a key element of this evaluation, particularly in a context where 66% of companies see tangible benefits from their industry 4.0 projects.

Feedback: lessons to be learned for your future projects

Feedback (REX) represents a valuable learning opportunity for the organization. This approach must be structured and involve all project stakeholders. The identification of good practices and improvement points enriches the company’s knowledge capital.

Documentation of these lessons facilitates the replication of successes and avoids the repetition of errors on future projects.

Tips for maintaining industrial project management in the long term

The sustainability of good project management practices requires management commitment and a culture of continuous improvement. Regular team training, procedure updates and adaptation to technological changes constitute the pillars of this approach.

The integration of project management into the company’s operational processes guarantees its sustainability and effectiveness in the long term.

Comparative table of industrial project management tools

| Software | Strengths | Pricing | Industrial specificities |

|---|---|---|---|

| Kantree | Strong customization | From €8/user/month | Cards are flexible in content and form |

| Monday.com | Intuitive interface, 200+ integrations | From €9/user/month | Customizable dashboards |

| Asana | Reliable, easy to use | From $10.99/user/month | Dependency management |

| Trello | Visual approach, Kanban | From $5/user/month | Ease of use |

| Smartsheet | Real-time collaboration | From €7/user/month | ERP integration |

| Jira | Highly configurable with IT | From €5/user/month | Incident management |

To go further

3 possibilities are available to you if this subject interests you:

If you found this article useful, consider sharing it. You can do so easily below.